Tool & Die Design / Build / RepairServices

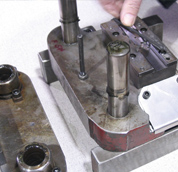

Paykra Tool and Die Inc. offers custom tool and die services including design/engineering, build/fabrication, repair/maintenance/ modification. We have experience with single operation and progressive dies as well as deep draw dies and custom machines. We are able to design and build dies to blank, pierce, draw, deep draw, extrude form and notch materials such as steel, stainless steel, aluminum, brass and copper as well as supply jigs and fixtures and custom machines. For those customers that do not want to stamp their own parts we also offer contract manufacturing. Paykra works to precision tolerances for all of our tool and die projects and have a well-equipped tool room and supplier network to ensure quick turnaround. Paykra Tool and Die Inc. offers custom tool and die services including design/engineering, build/fabrication, repair/maintenance/ modification. We have experience with single operation and progressive dies as well as deep draw dies and custom machines. We are able to design and build dies to blank, pierce, draw, deep draw, extrude form and notch materials such as steel, stainless steel, aluminum, brass and copper as well as supply jigs and fixtures and custom machines. For those customers that do not want to stamp their own parts we also offer contract manufacturing. Paykra works to precision tolerances for all of our tool and die projects and have a well-equipped tool room and supplier network to ensure quick turnaround.

We have extensive experience designing, building and repairing custom metal stamping dies for various industries and a wide range of applications. Additional information on our tool and die design services can be found in the following table or you can contact us directly to learn more.

Tool & Die Design & Fabrication Capabilities

| General Capabilities |

Die Design / Engineering

Die Build / Fabrication

Die Repair / Maintenance / Modification |

| Tooling Types |

Custom Metal Stamping Dies:

- Single Operation / Hit - Hand Transfer

- Progressive

|

Jigs & Fixtures

Custom Machines |

|

| Custom Metal Stamping Die - Operations |

Blanking

Piercing

Drawing

Deep Drawing

Extruding |

Forming

Notching

Bending

Cutting

Countersinking |

|

| Custom Metal Stamping Die - Materials Stamped |

Steel

- Cold Rolled

- Hot Rolled

- Hot Rolled Pickled & Oiled (HRPO)

- High Strength Low Alloy (HSLA)

- Annealed Spring Steel (C1050 - C1070)

|

Stainless Steel (301, 304, 316)

Aluminum (3003 ,5052)

Brass (Mill or Pre-plated Finish)

Copper (Mill or Pre-plated Finish)

Phosphorous Bronze |

|

| Tolerance (+/-) |

Tightest +/-0.001" (Depends on Operation)

Typical +/-0.005" |

Additional Information

| Industry Focus |

Automotive

Appliance

Construction / Building Products

HVAC

Hardware

Furniture (Office) |

Medical / Dental

Window / Door

Solar (Alternative Energy)

Electrical / Electronics / Electric Motors

Fabricators |

|

| Custom Metal Stamping Die - Intended Applications |

Clips

Cones

Flanges

Retainers (Bearing)

Plates

Washers

Brackets

Bus Bar

Terminals

Caps |

Brush Tubes

Clamps

Corners

Connectors

Latches

Washers

Covers

Housings

Hinges |

|

| File Formats |

AutoCAD

PDF

Images |

Back To Top |

(416) 741-2072

(416) 741-2072

Paykra Tool and Die Inc. offers custom tool and die services including design/engineering, build/fabrication, repair/maintenance/ modification. We have experience with single operation and progressive dies as well as deep draw dies and custom machines. We are able to design and build dies to blank, pierce, draw, deep draw, extrude form and notch materials such as steel, stainless steel, aluminum, brass and copper as well as supply jigs and fixtures and custom machines. For those customers that do not want to stamp their own parts we also offer contract manufacturing. Paykra works to precision tolerances for all of our tool and die projects and have a well-equipped tool room and supplier network to ensure quick turnaround.

Paykra Tool and Die Inc. offers custom tool and die services including design/engineering, build/fabrication, repair/maintenance/ modification. We have experience with single operation and progressive dies as well as deep draw dies and custom machines. We are able to design and build dies to blank, pierce, draw, deep draw, extrude form and notch materials such as steel, stainless steel, aluminum, brass and copper as well as supply jigs and fixtures and custom machines. For those customers that do not want to stamp their own parts we also offer contract manufacturing. Paykra works to precision tolerances for all of our tool and die projects and have a well-equipped tool room and supplier network to ensure quick turnaround.

Print This Page

Print This Page